Dubai Design Week, the Middle East’s premier design event, served as an extraordinary platform for showcasing the fusion of tradition and technology through Mitsubishi Estate’s groundbreaking 3D-printed teahouse. This innovative creation seamlessly integrated traditional Japanese culture and heritage with modern FDM 3D printing technology, offering an inspiring example of architectural ingenuity. Dynamism played a pivotal role in supporting the production of the teahouse components, which were crafted using a wood-based filament. These parts were later shipped to Dubai, where they were skillfully assembled into the final breathtaking structure.

Dubai Design Week: A Hub for Global Creativity

As the Middle East’s leading design event, Dubai Design Week attracts designers, professionals, and enthusiasts from around the world. Known for its ability to inspire creativity and foster innovation, the event features exhibitions, pop-ups, installations, and talks that engage participants while solidifying Dubai’s reputation as a global design capital. It’s within this vibrant environment that the 3D-printed teahouse stood out as a remarkable testament to the possibilities of blending cultural heritage with cutting-edge technology.

The 3D-Printed Teahouse: Where Tradition Meets Technology

The 3D-printed teahouse was a central highlight at Dubai Design Week, offering a powerful statement on how additive manufacturing can preserve cultural heritage while advancing the frontiers of architectural design. By merging traditional Japanese engineering techniques with state-of-the-art 3D printing, this project demonstrated the dynamic potential of modern technology to reinterpret historical craftsmanship.

Influences of Traditional Japanese Engineering

The teahouse’s design was heavily influenced by Japanese traditions, particularly the “hozo tsugi” joinery technique. This ancient practice involves creating interlocking wooden joints without the use of nails or screws, emphasizing durability and aesthetic precision. To authentically replicate the appearance and essence of this technique, the team utilized Polywood, a wood-infused resin filament. This material choice ensured that the 3D-printed components captured the visual and tactile qualities of traditional Japanese tea rooms.

Ultimaker’s Precision Printing

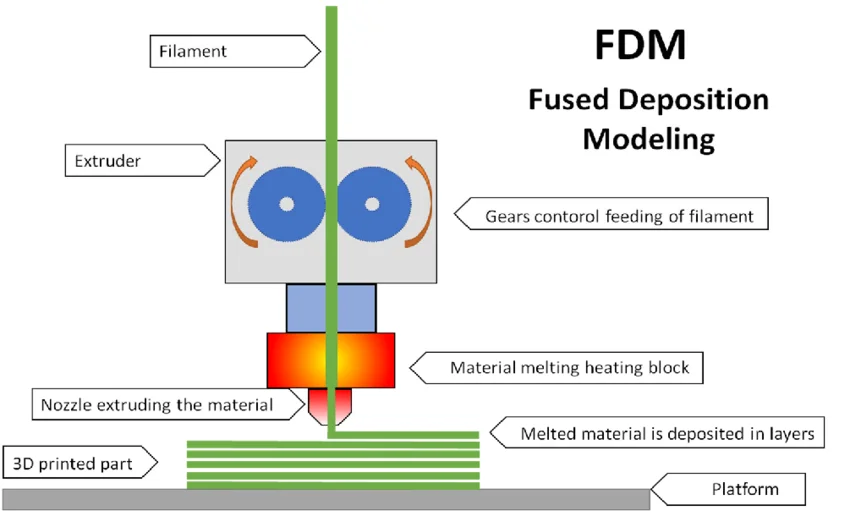

The success of this ambitious project was made possible by Ultimaker’s advanced S series 3D printers. The intricate design of the teahouse was digitally rendered and divided into 988 individual components, including 1,938 meticulously crafted “hozo” joints. Ultimaker’s printers delivered the precision required to produce these parts, completing approximately 4,000 hours of printing to bring the teahouse to life. The printers’ versatility allowed for the seamless integration of traditional engineering methods with advanced FDM (Fused Deposition Modeling) techniques, ensuring that every detail of the teahouse was both functional and true to its heritage.

The Cultural and Technological Significance

Beyond its architectural brilliance, the 3D-printed teahouse symbolized the harmonious blending of cultural heritage and modern innovation. By leveraging FDM printing technology, the project highlighted the transformative potential of additive manufacturing to preserve and reinterpret traditions. The teahouse captivated audiences from around the world, showcasing how modern tools can honor age-old practices while pushing the boundaries of design and engineering.

FDM Printing

Bridging Heritage and Modernity

The 3D-printed teahouse served as a bridge between the past and the future, demonstrating how traditional craftsmanship can coexist with and be elevated by modern technology. Dynamism’s contributions to the project underscored the expanding role of 3D printing in contemporary design, architecture, and engineering. The use of FDM printing not only showcased technological capabilities but also emphasized the importance of preserving cultural identity in an increasingly digital world.

The Role of Dynamism and Mitsubishi Estate

Dynamism’s expertise in advanced 3D printing solutions was instrumental in bringing this project to fruition. By providing the necessary technology and support, the company ensured that the teahouse components were printed with exceptional accuracy and quality. Mitsubishi Estate’s vision for the project further highlighted its commitment to blending tradition with innovation, setting a benchmark for future architectural endeavors.

Dubai Design Week: A Celebration of Innovation

Dubai Design Week provided the ideal stage for this groundbreaking project, reinforcing the event’s reputation as a global hub for creativity and innovation. The 3D-printed teahouse not only captivated audiences but also sparked conversations about the role of technology in preserving and enhancing cultural heritage. By combining traditional Japanese engineering with the precision of Ultimaker’s FDM printing, the project demonstrated how modern tools can breathe new life into historical practices.

FDM Printing

Read more: FDM 3D Printing and Ultimaker Spotlighted at Dubai Design Week